There are many options for a battery to power an astromech, from the tried and tested Sealed Lead-Acid, to the latest LiFePO4. This article will look at utilising the very common 18650 cells. These are used in power tools, laptops, even Tesla cars.

WARNING, this article will talk about opening old packs, harvesting their cells, soldering cells, spot welding cells, and lots of other things that could be quite dangerous.

Lithium cells of any type can heat up or burst into flames if mistreated. Only attempt the things in this article if you are entirely comfortable with any possible outcomes. Do other research, read other articles, the author accepts no responsibility for any injuries or death from the instructions given.

General theory

18650 refers to the size of the cells, 18mm x 65mm. They generally have a capacity between 1500 and 3500mAh. If you see anything saying 4000mAh or above, chances are its a scam. There are a lot of cells branded ultrafire that claim over 6000mAh capacity which is a total lie. Voltage ranges from 4.2v when full, to 3.2v when empty. These cells use Lithium-Ion technology, which is a lot safer than the Lithium Polymer that is used in many radio control devices. The drawbacks are that it has a much lower discharge rate. LiFePO4 are even safer, but are also more expensive. Li-Ion seems to be a middle ground, which is why it is used in so many places.

Generally, these cells are arranged in series/parallel to get the desired voltage and capacity. For example, a 24V battery is made of 6 cells in series. Extra capacity is added by putting more cells in parallel, so that if you use cells with 2500mAh capacity and want a 24V battery with 10Ah capacity, then you will use 4 rows of 6 cells, commonly written as 6s4p.

The current drain allowed on a battery is usually 1C, or 1*<capacity>, so in the same example 6s4p battery, you can have a maximum drain current of 10A. Doubling the battery up to be a 6s8p will give you 20Ah and a 20A potential drain. 1C is the safe limit using recycled cells. If you are using brand new cells then you may be able to get a higher current draw by checking the datasheet. For example a NCR18650B can draw 2C and a NCR18650PF can go up to 3C.

Sources

Cells

As mentioned above, 18650 cells are used in many places, and can generally be recycled. The best place I have found for second hand cells is from laptops or power tools. These battery packs can be cracked open and the cells removed. It is quite a labour intensive task, but saves a lot of money. You can pick up job lots of second hand cells from eBay, tho this is getting more expensive as more people are harvesting cells this way.

You have to force the two halves of the battery case apart, usually with a screwdriver or similar flat sharp object, and then separate the cells from the circuitry and cabling inside. Always wear heavy gloves, and take extra care when using a lot of force. Its easy to slip and damage yourself or the batteries. Also make sure to take care not to use the cells as a fulcrum as this will also damage the cell. Basically, be careful and take your time.

An Opus BT-C3100 18650 charger/tester

The drawback is that each cell is of unknown capacity and life, some cells may even be totally dead. They could already have been through a few thousand cycles. Each cell needs its capacity testing with a charger/tester such as the Opus BT-C3400. Of course, if you can ask friends and family for donations of old laptop batteries, you can save even more money. I managed to get a lot donated for free. Despite the drawbacks and amount of work required, you can end up with a battery for next to nothing that would cost a lot if you bought a ready made one. For example, I built a 24V 25Ah (approx) 6s11p for around £50 of cells, plus a few other bits.

The other option is to buy brand new cells in bulk. Either from Chinese sites such as aliexpress.com, or from other sites closer to home such as eu.nkon.nl. Chinese ones are generally a little cheaper, but you do have a long lead time and the risk they are counterfeit. A typical cell such as the NCR18650B (high capacity/average discharge rate) or NCR18650PF (medium capacity/high discharge rate) can be bought for approx £3 a cell.

Additional

As well as the actual cells, there are a couple of other essentials. These are cell spacers, which clip into various configurations to hold the cells in place, and allow air flow around them. You’ll also need nickel strip to connect all the cells together. Both of these items can be bought from aliexpress.com in bulk. If you are buying brand new batteries from NKON, they also sell nickel strips for a decent price when bought in batches of 10m.

Lastly, you’ll need battery connectors and a balance lead. The battery connector can be anything you wish, as long as it will take the current. The balance lead is a connector so you can make sure that all the series cells are at the same voltage. This is important so you don’t let one cell run down lower than the others, which will potentially damage the cell, and maybe the whole battery. You need one for the correct size of battery (eg, a 6s battery will need a 7 wire balance lead) which can be got again from aliexpress.com or ebay.

Constructing the battery

Once you have enough cells together, and all the other items, time for construction. The general process is:

- Sort the batteries into parallel sets with the same total capacity. The idea is to have them well balanced before you even start. You can use a site such as repackr.com to help with that

- Clip the cell spacers together in the required layout (eg 6×12 for a 6s12p), then lay the cells out. Each parallel set should be the same orientation (eg, negative to the top), but alternate them as you fill in the series set.

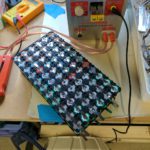

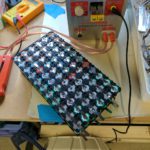

The start of a 6s12p pack. Can see the parallel sets run down the picture, with the series sets alternating across

- Once you have all the batteries in place, clip the top of the frame into place

Here is a small 3s5p pack, ready for the nickel strips

- Now its time to connect the parallel sets up. Using either a soldering iron, or a spot welder, connect strips along all the parallel sets. These are the ones that are all the same way up. What this does is create the capacity for battery pack. Be careful if soldering, don’t allow too much heat to build up on the cell, do it as quick as possible. You can get spot welders from aliexpress.com for around £200 that will do the job a lot better.

You can also get a device that will give you a full readout, just from plugging the balance connector in. They are only a few pounds from places like ebay. They will let you view the total voltage, each parallel set voltage, and also the max/min/dif between the cells.

For the initial charge you will need to use a decent balance charger, such as an imax B6. These are generally for lipo batteries, used in radio controlled quad copters or planes. The benefit of a charger like this is that it will balance the cells out and has lots of monitoring and protection built in. Follow the instructions in the charger manual closely.

Testing

Once charged, leave your pack for a while, even a month, testing the voltages periodically. If you have a dead cell, then it can manifest as one of the parallel sets slowly loosing charge. When this happens, you’ll have to dismantle the battery and retest all the cells.

If you have the time, you can also do a full discharge test with the charger on the battery to get an accurate reading of its capacity. This will take a long time if you’ve made a big battery, depending on the charger you use. If you aren’t overly bothered about an accurate capacity test, just run the battery in the droid (or whatever other use) and monitor the voltage. Don’t let the voltage go down below 3*<number in series> (eg, a 6s should never be let to dip below 18v). To prolong the life of the battery, don’t even let it go that far. Full charge/discharge cycles are the worst case for wear on them, and will shorten the lifespan. I recommend discharging it to around 40-50%, at least on the first try.

After the first discharge, check the balance of the cells again. Ideally there should be little difference between them in a fully functional battery pack. If there is significant difference (IMHO, 0.1v between the highest and lowest voltage) then you may have a bad cell somewhere. Do another balanced charge and discharge cycle and see if the same cell has troubles. If it does, rip it apart and try again.

If the battery remains balanced, then you can actually use a none balance charger (cheaper, and usually higher current for rapid charging) for most charge cycles. Tho make sure it is balanced occasionally and no harm in doing a slow balanced charge once in a while.

Conclusion/Notes

Using 18650 cells gives you great flexibility in not only the size (voltage and Ah), but also the shape. This example has shown creating standard blocks, but with some creativity you can make a battery that follows a certain shape (ie, follows the outer curve of an R2 unit’s interior). If you want to make use of recycled cells, then this is a very cheap option to get some very high capacity batteries built. Even buying brand new cells will still save you a lot of money.

For example, I’m currently building a 6s12p pack using NCR18650B cells. I’m getting these for approx £3 a cell. That makes the total cost of cells £216, which gets me a 24V/40Ah capacity battery in a fairly small form factor that can give out nearly 80A (my droid barely pulls 10A at full speed!). I doubt I could fit enough SLA batteries in my droid to get that, and a similar capacity of LiFePO4 would set me back about £800. Even taking into account the cost of a spot welder (which can be used many times of course) its double the price.

Further research

One thing I haven’t covered in this article is a BMS. This is a Battery Management System makes sure nothing is going wrong with it, and will cut off the output when the battery gets too low. I’m still researching these myself, and will possibly mess with them on my next pack. IMHO, if you are keeping an eye on the battery voltage during use and doing periodic balance tests and charges, then a BMS is not necessary.

Also note that capacity of the cells will drop over time, depending on number of cycles, how deeply they were charged/discharged, and how rapidly they were discharged. Take care of the battery, and it will last longer, drain it constantly at high current and it will be dead within a few hundred cycles.

As I brought him in and scouted out the place, I encountered a few handling problems. It appeared that I’d lost one of the shims from a foot which meant one of his drive wheels wasn’t getting the grip it should. This led to him veering off to the right all the time and at one point he encountered a stall and destroyed a lego figure! After apologising profusely, I found a corner to sit him in and waited for the crowds to appear.

As I brought him in and scouted out the place, I encountered a few handling problems. It appeared that I’d lost one of the shims from a foot which meant one of his drive wheels wasn’t getting the grip it should. This led to him veering off to the right all the time and at one point he encountered a stall and destroyed a lego figure! After apologising profusely, I found a corner to sit him in and waited for the crowds to appear.

This year has been a bit busy so far, and in February I realised I only had something like three free weekends to get R2 ready for his first outing,

This year has been a bit busy so far, and in February I realised I only had something like three free weekends to get R2 ready for his first outing,  And more bits were added, I got his skirt installed finally, after having bought it nearly a year ago. This however involved some fairly major dismantling of R2, which in turn meant I had to finally get the sled finished for him. Overall, I’m quite pleased with the sled, and it allowed me to lay him down gently and take his legs off to get into the base of the frame.

And more bits were added, I got his skirt installed finally, after having bought it nearly a year ago. This however involved some fairly major dismantling of R2, which in turn meant I had to finally get the sled finished for him. Overall, I’m quite pleased with the sled, and it allowed me to lay him down gently and take his legs off to get into the base of the frame.

I have more or less got the legs finished, and have done a test fit! Must say, they are looking rather good. All the parts slot nicely together and are pretty solid. Of course, I still have the problem of a lot of the screws and bolts being imperial (We’re part of the rebel alliance, don’t want any of that imperial rubbish!) rather than metric, so getting hold of replacements can be tough. This is more of a problem seeing as I’ve had some of these parts for quite a while and not only been moved around the office in the old house, but have moved to the new house and gone in and out of the garage, so some of the fastenings have been misplaced along the way.

I have more or less got the legs finished, and have done a test fit! Must say, they are looking rather good. All the parts slot nicely together and are pretty solid. Of course, I still have the problem of a lot of the screws and bolts being imperial (We’re part of the rebel alliance, don’t want any of that imperial rubbish!) rather than metric, so getting hold of replacements can be tough. This is more of a problem seeing as I’ve had some of these parts for quite a while and not only been moved around the office in the old house, but have moved to the new house and gone in and out of the garage, so some of the fastenings have been misplaced along the way.