My Own Lightsaber

R2 is progressing nicely, solar stats are gathering, and I’m waiting for parts for my powerwall project. To add to the list of projects, and to learn techniques on the lathe and mini-mill, I’ve decided to build my own lightsaber.

If you want a lightsaber, there are plenty of options. Cheap ones, off the shelf decent ones, upgraded ones, custom ones, and even kits. As I want to learn machining skills I am going down the custom DIY route.

Saber Parts

A saber in its simplest for is:

Sound Board

This is a small board with an accelerometer, LED driver, speaker driver, and a couple of inputs for buttons, with a microcontroller to tie it all together. From research and conversations with my friend Neil (who has his own saber shop, London Sabers) I decided to go with a sound board from a company called Plecter Labs. This is a home run shop that produces a range of sound boards of differing complexity. The boards can be bought in the UK from JQSabers. That is also where I got a lot of the other parts that I needed.

Test wiring of sounds board and other components

LED

These days you have a choice between a single LED cluster in the hilt, or a string of LEDs that run up the inside of the blade. With a string of LEDs you can have a gradual light up of the blade that looks more like the film, but with a single LED cluster in the hilt it makes the blade a lot easier to remove. To keep things simple, my lightsaber will just have a single LED cluster in the hilt. I’ve gone with the Tri Cree XP-E2 which has two blue and one white LEDs on a small circuit board. The white LED allows for something called ‘Flash On Clash’ which, as it sounds, means that when the sound board detects that you’ve hit something, the blade will pulse with an extra white light.

Tri Cree LED

Hilt

This is the part that will be 100% custom for me. There are modular options available, or replica ones if you want something from the film. I’m doing a totally custom design and will all be machined by me on the lathe and mini-mill. It will be a fairly simple design (for this one at least) as my skills on the lathe are not exactly the best yet.

Emitter end of the hilt

Turning the main part of the hilt, adding some cosmetic details

Blade

The blade is just a simple tube with reflective film on the inside to give a smooth lighting. As I want to be able to hit things with my lightsaber, I’ve gone for the thick walled dueling blade.

Progress

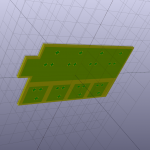

So far, I have made the emitter and main part of the hilt, along with doing a test wiring of all the electronics to go inside of it. Quite pleased with how the hilt is coming along, I just need to wait for my new mini-mill to turn up so that I can accurately drill some holes and create areas for the switch to sit. The pommel end of the hilt still needs to be designed, and will house the main speaker. Currently I’m working on some laser cut parts that will hold the internals in place, yet still be easily removed for servicing.

The start of the skeleton for the internals